According to Royal Mail MarketReach, advertising mail is engaged with 94% of the time. It’s more memorable too—specifically 35% more than social media and 49% more than email marketing.

With that kind of response, it’s easy to see why the demand for direct mail is on the rise, which means any gaps or inefficiencies you have in your production processes will become exaggerated and even more apparent as more—or larger—projects come your way.

If you’re a direct mail printer, you are fully aware of the nuances, complexities, and potential pitfalls that are part and parcel with direct mail projects. And if you’re a commercial printer that’s exploring direct mail as a new revenue stream, perhaps you’re starting to find out.

No matter which of those describes your business, if slow or inaccurate estimates are causing you to lose bids, if production issues lead to missed deadlines or limited capacity, or if missing or incomplete instructions (e.g., fonts, proofs, mail drops, etc.) are creating costly errors that erode your profit margins, you need a structured, organised project environment. This will enable you to create accurate estimates, determine the most efficient route through production, and capture all the detailed instructions, intermediate milestones, and events that ensures each piece of mail reaches its destination in the most cost-effective way possible—no matter how simple or complex the project may be.

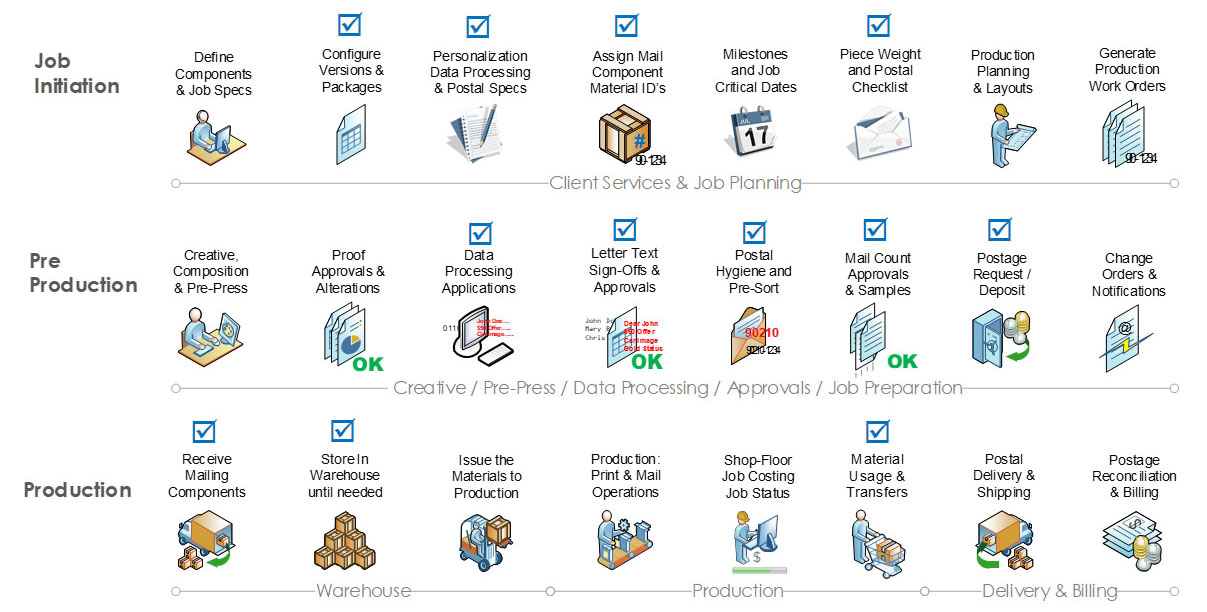

Additional processes in a direct mail production workflow

Additional processes in a direct mail production workflow

Take the stress out of your operations

Direct mailers can benefit from new solutions that improve the efficiency and accuracy of their production workflows in some or all of the following areas:

- Estimating and proposal generation

- Job creation and planning

- Job instructions and checklists

- Production work orders/job tickets

- Job milestone management

- Scheduling and capacity planning

- Material purchasing, reservation, and allocation

- Production and shop floor monitoring

- Accurate costing and billing

While this may seem a bit overwhelming or even arduous at first, making workflow improvements doesn’t have to be an all-or-nothing proposition. Some direct mailers and commercial printers find it more manageable to solve their highest priority challenge(s) first and work their way down the list as they gain traction and see positive results.

Become a trusted partner in a shifting market

Until now, many direct mailers have focused on small, incremental improvements to their existing processes, but they were missing the ultimate target—seeking dramatic improvements in the efficiency and profitability of their operations.

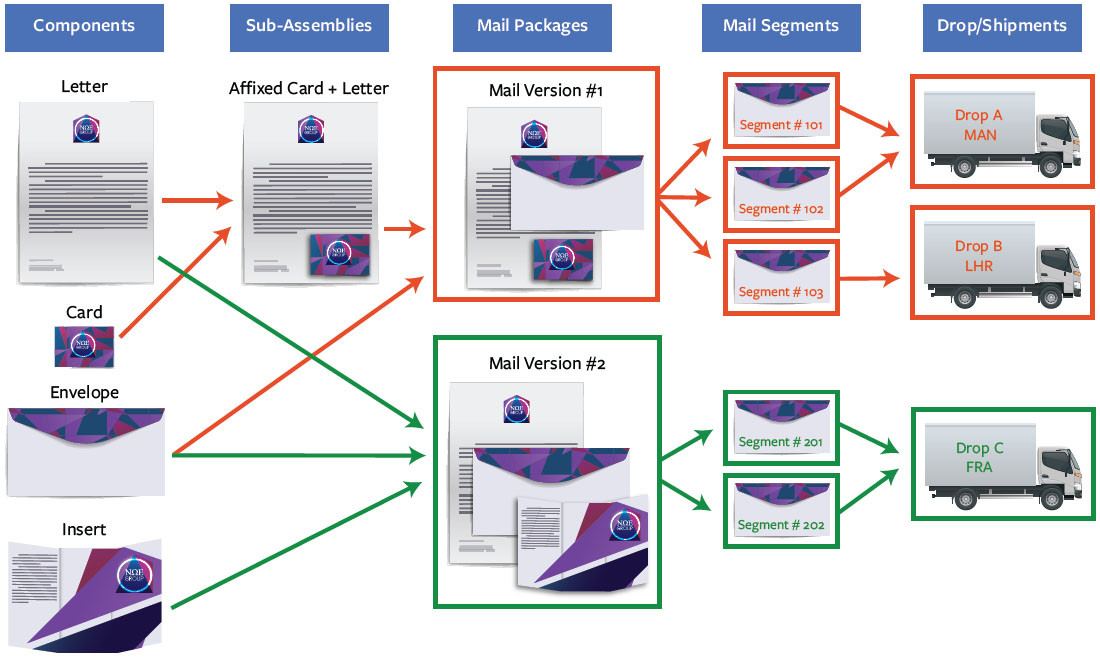

Complexities in a modern direct mail project

Complexities in a modern direct mail project

While mailing projects may be decreasing in volume, they’re also increasing in complexity due to number of versions, variable data permutations, number of mail drops, etc. that are required to capture a recipient’s attention and achieve the desired result.

The tools and processes you use to manage these projects must be specifically designed to help businesses like yours solve the most inefficient, error-prone, and profit-draining business processes in a direct mail operation to set you up for success.

With the right purpose-built solutions and processes in place, you will be able to win more direct mail business, increase capacity, improve efficiency, reduce errors, and ultimately maximise profitability on everything from simple repeat jobs to complex, one-off projects with multiple components and hundreds of versions. Learn more about how eProductivity Software’s mailing workflow solutions are specifically designed to help mailing organisations improve the efficiency and profitability of all direct, transpromo, and transactional mail projects.

Learn more about how eProductivity Software’s mailing workflow solutions are specifically designed to help mailing organisations improve the efficiency and profitability of all direct, transpromo, and transactional mail projects.

Nick Benkovich is VP, Portfolio Product Management, eProductivity Software

Nick Benkovich is VP, Portfolio Product Management, eProductivity Software